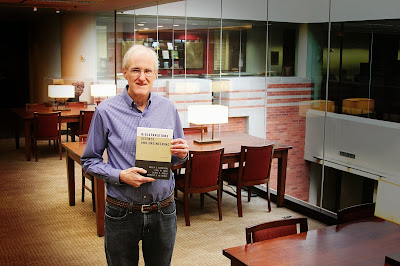

CBME professor, Roger Harrison, publishes new edition bioseparations book

The demand for highly purified

biological products for commercial and consumer use has increased significantly

over the past decade, leaving a widening gap between the application and

engineers trained in the process. To respond to the growing need to separate

and purify these bioproducts, Roger Harrison, University of Oklahoma College of

Engineering professor in the School of Chemical, Biological and Materials

Engineering and also in the Biomedical Engineering Center, has released a revised

edition of the book “Biosepartions Science and Engineering” along with co-authors

Paul Todd, Scott Rudge and Demetri Petrides.

New to the second edition are

updated descriptions of the important chromatography separation method, which

is required for the purification of bioproducts that must be injected into the

bloodstream. As in the first edition, the various operations in bioseparation

processes are explained by first developing the scientific basis and

mathematical theory and then describing the applications of the theory in

engineering practice with an emphasis on design and scale-up. Aimed at students

and industry practitioners, the book also includes updated cost information and

expansion of the chapter on bioprocess design for the integration of various

bioseparation operations to develop economically optimal processes.

More than 60 universities worldwide

teach courses using the “Bioseparations Science and Engineering” textbook, a

powerful testament to the growing necessity of biotechnology development and

implementation throughout the world.

“As the world relies more on the

development of new biotechnology products in the pharmaceutical, agricultural

and specialty chemical industries, science and engineering will depend on efficient

bioseparation processes to meet the demand,” Harrison said. “This revised

edition addresses today’s growing need to educate a new generation of

scientists and engineers requiring up-to-date capabilities for developing new

bioseparations processes.”